The newer LD02B DIY kit is described here (introduced Dec. 2009)

- this document is for the original LD02 DIY kit.

The LD02 display (described here) replaces the LD01 display.

Internally LD02 is more complex than the LD01, primarily because it interprets the RS232 data stream from WBo2 rather than reading

a voltage level (this eliminates errors that are possible with voltage level displays).

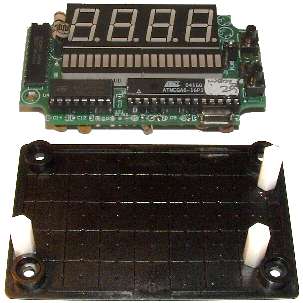

Electronically, rather than the direct connection of the Tiny26 to the LD01's LEDs, the LD02's Mega8 has external source

and sink drivers that are connected to a single 4 digit muxed display and 2 ten-segment bargraph displays.

LD02 is fairly simple to assemble with most of the parts being semiconductors and decoupling capacitors.

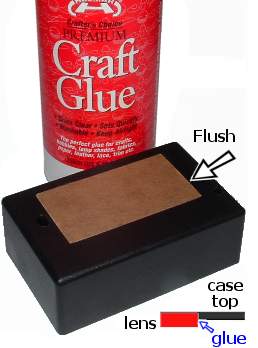

The LD02 DIY kit includes all parts (case, perspex cover, cable, PCB, all parts, etc.) necessary to build the unit.

You have to add solder, some glue, and time to construct it.

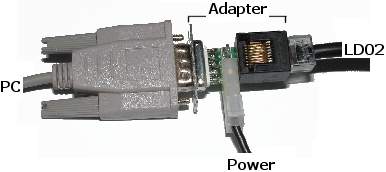

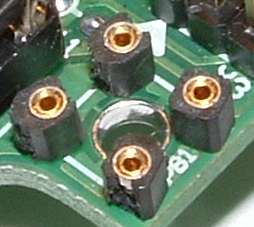

The re-programming interface adaptor is shown in schematic format at left.

All components on the PCB are shown within the green area.

Connections to the adaptor are shown around the PCB.

The white Molex® two pin socket (top of schematic) connects to the WBo2 power cable (which we assume you are using during re-programming).

The DB9 is for connection to a PC's RS232 cable.

The LD02 itself connects to the 8 pin RJ45 connector (only the RJ45's active 4 pins are shown in the schematic).

The re-programming interface adaptor is shown in schematic format at left.

All components on the PCB are shown within the green area.

Connections to the adaptor are shown around the PCB.

The white Molex® two pin socket (top of schematic) connects to the WBo2 power cable (which we assume you are using during re-programming).

The DB9 is for connection to a PC's RS232 cable.

The LD02 itself connects to the 8 pin RJ45 connector (only the RJ45's active 4 pins are shown in the schematic).